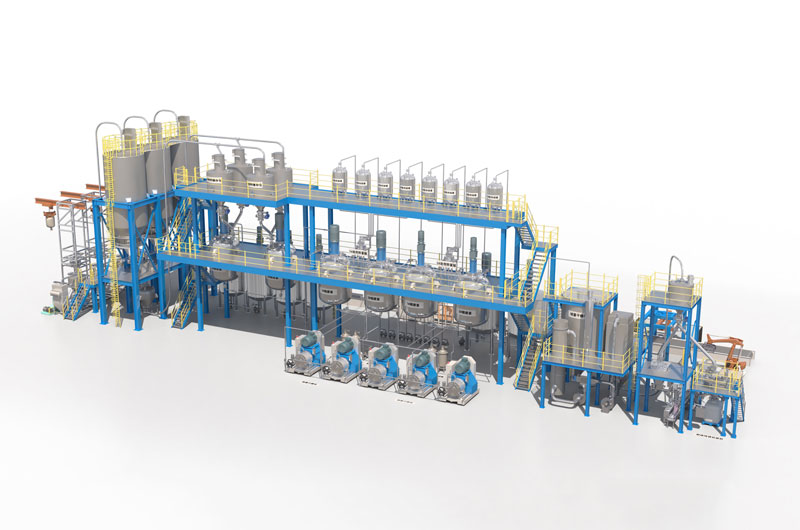

Winray nano powder flexible intelligent production line, the whole production process is completely closed and environmentally friendly, which can realize the accurate batching of powder raw materials and liquid raw materials, automatic conversion of emulsification, rough grinding and nano grinding, automatic spray milling of nano slurry, and automatic packaging of nano powder. The entire production process is automated, digitized, and intelligently controlled, with stable quality, flexible compatibility of each process, dynamic material balance, and maximizing product quality and production capacity.

The main equipment includes ton bag and small bag combined feeding station, powder batching and conveying system, liquid batching and conveying system, auxiliary agent storage and weighing system, bar pin nano sand mill, filtration system, demagnetization system, spray drying system, nano powder packaging system, pipeline valve instrument, steel structure platform, automatic control system, etc., which is suitable for grinding materials with particle size of 50-300nm.

Language

Language Current Location :

Current Location :