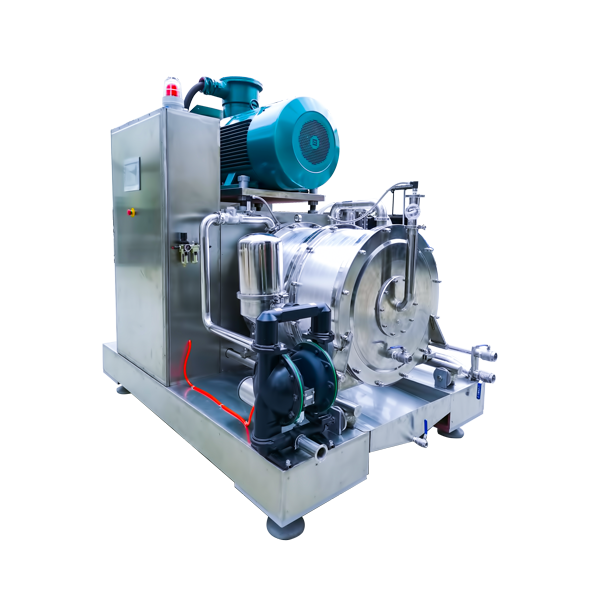

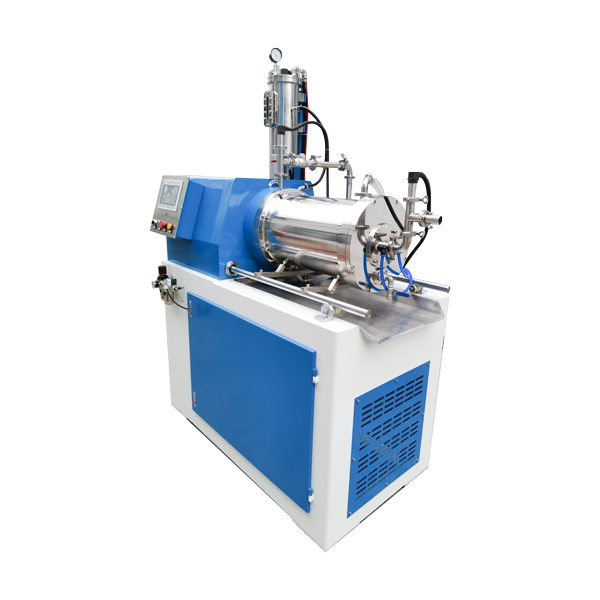

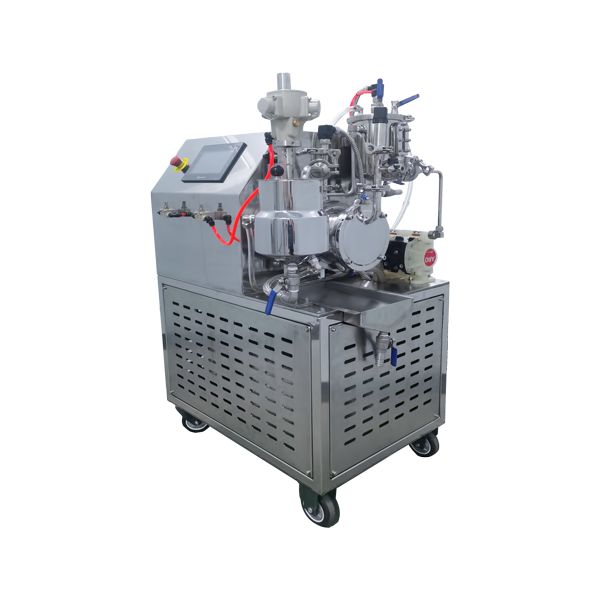

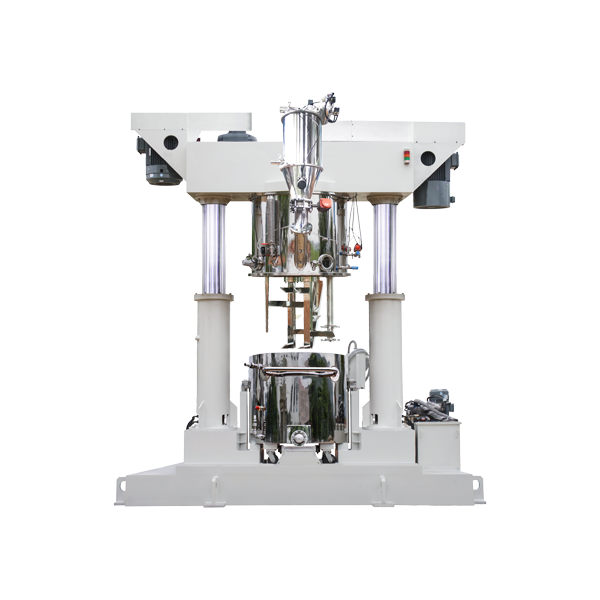

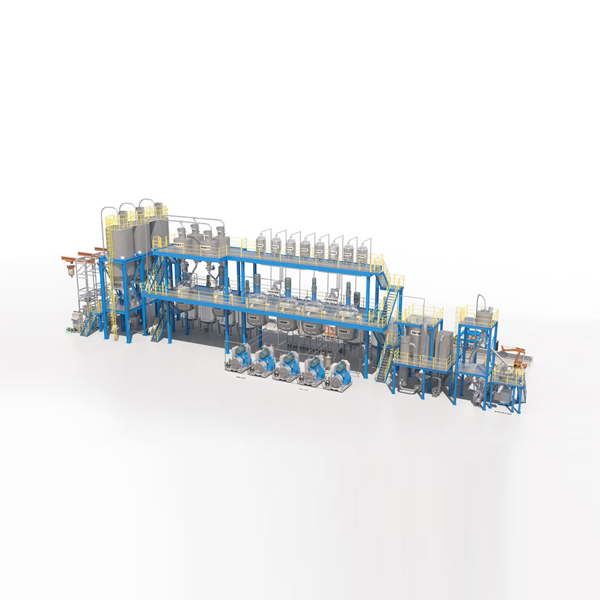

Discharge fineness: < 300 nm

Medium particle size: 0.1-0.3 mm

Discharge method: Centrifugal separation sieve tube discharge

Grinding chamber volume: 5/10/15/25/30/60 (L)

Grinding chamber material: Silicon carbide

Grinding rotor material: ceramic/PU/alloy steel

Grinding rotor type: rod pin type

Language

Language

021-69002362

021-69002362