Shanghai Winray has long focused on safe and healthy food processing and research, providing intelligent equipment and production line construction services for the food manufacturing industry, and ensuring that its products meet GMP requirements. Services include food processing industry, vegetable oil processing industry, sugar manufacturing industry, condiment manufacturing industry, food additives, dairy manufacturing, beverage manufacturing, meat processing industry, essence, spices and other food processing.

Main Equipment and Functions in the Food Industry:

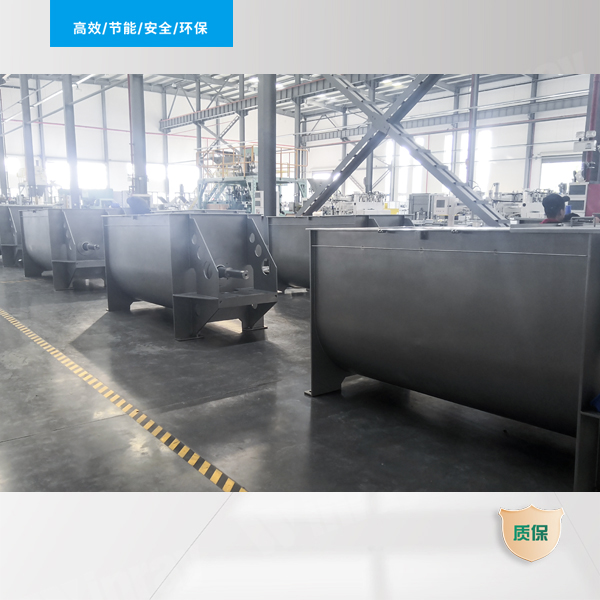

1 Mixer: Mixing powders with powders, and powders with small amounts of liquid.

2 Unpacking and Feeding Equipment: Includes unpacking of small bags and ton bags, available in semi-automatic and automatic versions.

3 Packaging Machines: Includes valve bags and open bags. Standard packaging sizes are: under 5kg, under 50kg, and ton bags.

4 Emulsifiers: Used for dispersing, homogenizing, emulsifying, and refining food additives. Classified by type as intermittent or inline; based on production process, they can be categorized as flow-through emulsifiers, top-spray emulsifiers, high-shear dispersion emulsifiers, solid-liquid mixing emulsifiers, etc.; and can be designed with vacuuming, heating, and other methods according to process requirements.

5 Food Additive Production Line: Single-machine equipment combination or fully automated production line, including advanced production methods such as feeding system, metering system, mixing and stirring system, automatic control system, and automatic packaging system, customized according to different food varieties and production requirements.

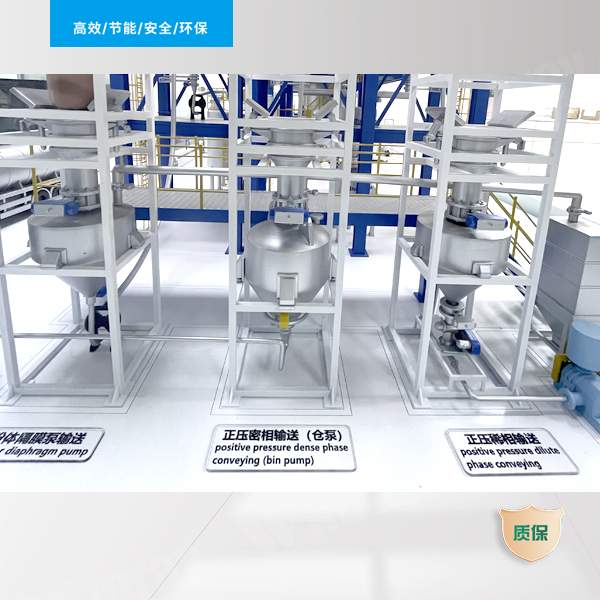

6 Powder and Liquid Conveying Systems: Powder pneumatic conveying (positive pressure, negative pressure, dense phase, dilute phase), mechanical conveying (screw, belt, bucket elevator, etc.); liquid positive and negative pressure conveying, pumping.

7 Powder and liquid batching system: Includes various batching methods such as "incremental method", "reduction method", and "volume method".

8 Storage silos: Includes liquid storage silos and powder storage silos.

9 Dust removal equipment: Bag filter dust collectors, cartridge filter dust collectors, and silo top dust collectors.

Language

Language

Current Location :

Current Location :