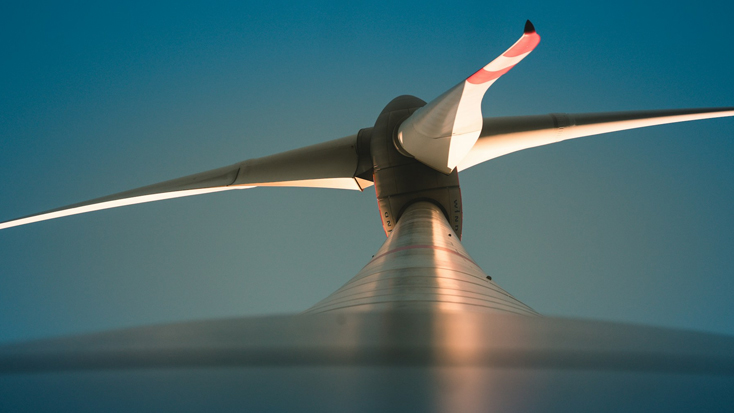

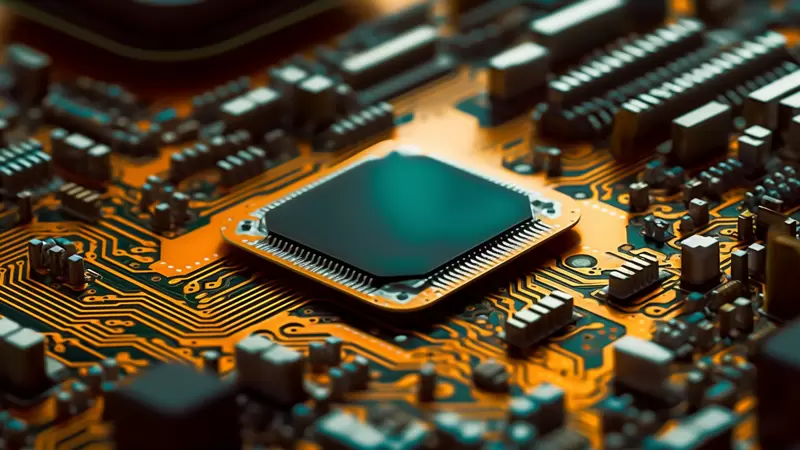

Main equipment and functions of new energy materials

1.行星搅拌机: 专为锂电池浆料设计,具备独特的螺旋搅拌桨和3D设计,通过四轴加工中心加工。结合高速分散剪切机,实现浆料的快速和均匀混合。

2. Horizontal drying mixer: suitable for drying and mixing anode materials, providing explosion-proof customization. Suitable for water-based and solvent based products to reduce metal contamination, improve product quality and production efficiency.

3. Blender: including vertical and horizontal designs, mainly used for batch mixing. The mixing chamber can be coated with tungsten carbide or lined with polyurethane to reduce metal contamination.

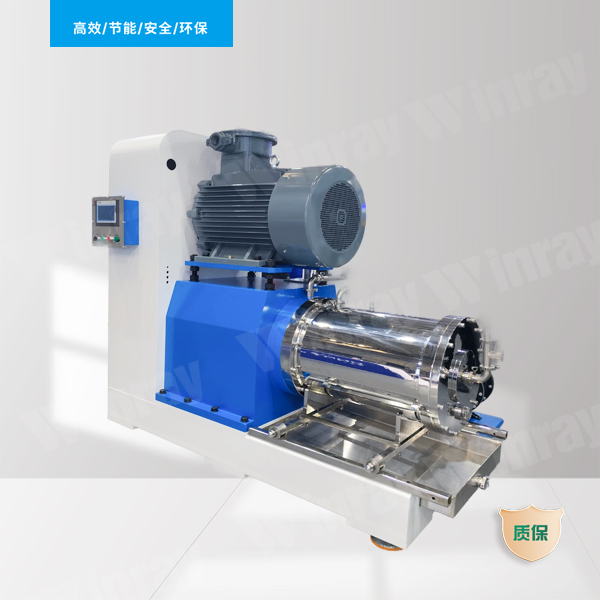

4. Grinding machines: nano sand mills, micro sand mills, laboratory sand mills, basket grinders, three roll grinders, etc

5. Vacuum conveyor: used for powder conveying, adopting vacuum suction and closed transmission methods, which helps improve the production environment.

6. Packaging machine: used for packaging lithium battery negative electrode materials, providing various packaging specifications and forms.

7. Battery slurry production line: a fully automatic, enclosed production line aimed at improving efficiency and safety.

8. Powder and liquid conveying system: including powder pneumatic conveying (positive pressure, negative pressure, dense phase, dilute phase) and mechanical conveying (spiral, belt, bucket, etc.), as well as liquid positive pressure and negative pressure conveying, pumping.

9. Powder and liquid batching system: Provides various batching methods such as "incremental method", "reduction method", and "volume method" to ensure accurate batching and mixing.

Language

Language

Current Location :

Current Location :