Main equipment and functions in the ink industry

1、分散机:油墨预分散,多种规格和形式可选,从实验室到生产型,包含带刮壁式分散机、真空型分散机、蝶式双轴分散机,平台式分散机等各种机型,满足各种分散工况要求。

2. Basket grinder: Ink grinding equipment that combines the original dispersion and sanding processes into one, reducing the process flow, eliminating the need for pumps and valves, improving production efficiency, reducing material waste, easy cleaning, and suitable for grinding multiple types of products.

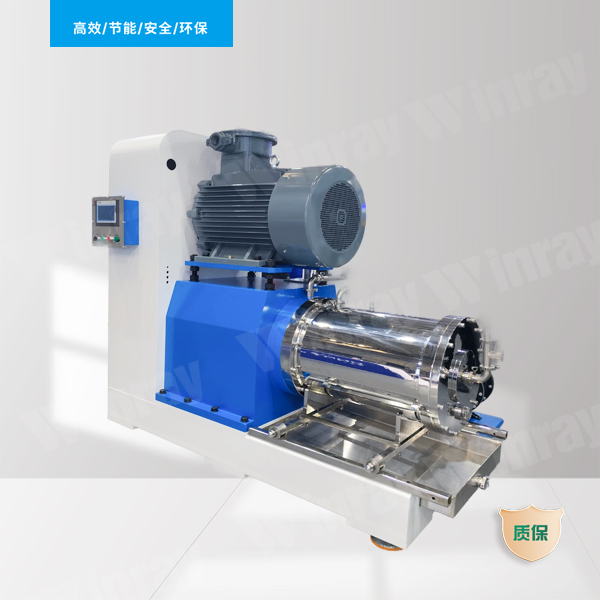

3. Horizontal sand grinder: a wet grinding equipment for ink products with high fineness requirements, with good grinding fineness and high efficiency. It is the most widely used grinding product in the market, including disc type horizontal sand grinder and versatile horizontal sand grinder.

4. Three roll grinder: a grinding equipment for ink products with high viscosity, available in two forms: ordinary and hydraulic, making it an ideal grinding equipment for ink.

5. Blender: There are various forms and specifications of mixers available for different production processes and material characteristics (viscosity, specific gravity, etc.) of ink, including vacuum, explosion-proof, single axis, double axis, three-axis, and planetary mixers for high viscosity ink.

6. Filling machine: Packaging specifications range from 10g to 20kg, suitable for filling plastic and iron drums, including semi-automatic and fully automatic forms, and can be customized according to requirements.

7. Ink production line: a combination of single machine equipment or fully automated production line, including advanced production methods such as feeding system, metering system, horizontal sanding&three roll grinding system, multifunctional stirring system, automation control system, automatic filling, etc., customized according to different ink varieties and production requirements.

Language

Language

Current Location :

Current Location :