Main equipment and functions in the paint industry

1、分散机: 用于涂料和乳胶漆浆料的预分散。提供多种类型和规格,包括带刮刀的分散机、真空型分散机、带蝶形搅拌器的双轴分散机、平台型分散机等,以满足不同的分散和混合需求。

2. Basket grinder: a wet grinding equipment that integrates dispersion and grinding processes, reduces production steps, eliminates the need for pumps and valves, improves production efficiency, reduces material waste, is easy to clean, and is suitable for small-scale production of various products.

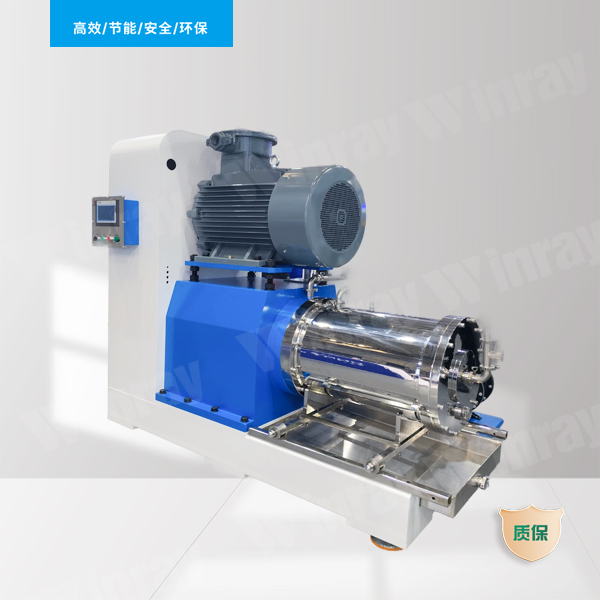

3. Horizontal sand grinder: used for wet grinding of high fineness materials, with excellent grinding effect and high efficiency, including disc sand grinder and rod pin sand grinder.

4. Blender: can be selected according to different processes and material characteristics, including vacuum type, explosion-proof type, single axis type, double axis type, and three-axis type mixers.

5. Paint filling machine: Filling specifications range from 0.5 kg to 200 kg, suitable for plastic and metal drums, including semi-automatic and fully automatic types, and can be customized.

6. Paint production line: With a capacity ranging from 500T/year to 50000T/year, it can be customized according to the type of paint and production requirements, including feeding, measuring, dispersing and grinding, mixing and coloring, cleaning, automatic control and other systems, with explosion-proof or non explosion-proof configurations.

7. Powder and liquid conveying system: including powder pneumatic conveying (positive pressure, negative pressure, dense phase, dilute phase), mechanical conveying (spiral, belt, etc.); Liquid positive and negative pressure conveying, pumping.

8. Powder and liquid batching system: Provides batching methods such as "incremental method", "reduction method", and "volumetric method".

Language

Language

Current Location :

Current Location :