Main equipment and functions of pharmaceutical intermediates

1、混合机: 用于粉料与粉体、粉体与少量液体的混合,采用独立的可计量喷雾式方法,提高混合效率和均匀性。提供全系列规格,包括实验室和生产型设备,多种形式如立式和卧式,可根据生产工艺和物料特性选择最适合的设备。

2. Unpacking and feeding equipment: including small bag and ton bag unpacking, divided into semi-automatic and automatic types to meet different production needs.

3. Conveyor: including pneumatic conveying (positive pressure, negative pressure, dense phase, dilute phase) and mechanical conveying (screw, bucket lift, pipe chain, belt), to meet different material conveying needs.

4. Packaging machine: Provides valve pocket and open pocket packaging, with regular packaging quantities of 5kg or less, 50kg or less, and ton bag packaging to meet diverse packaging needs.

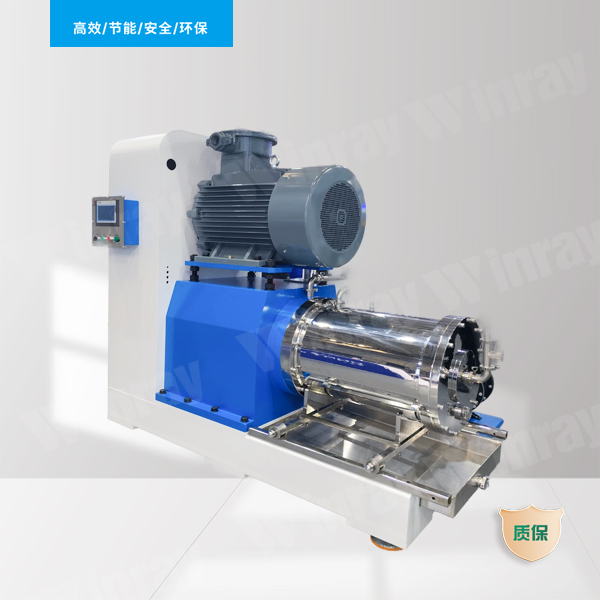

5. Emulsifier: Used for dispersing, homogenizing, emulsifying, and refining pharmaceutical intermediates, it offers two forms: gap type and pipeline type, including jet flow type, upward spray type, high shear dispersion, and solid-liquid mixing emulsifier. It can be designed with various process methods such as vacuum pumping and heating.

6. Powder and liquid conveying systems: powder pneumatic conveying (positive pressure, negative pressure, dense phase, dilute phase), mechanical conveying (screw, belt, bucket elevator, etc.); Positive and negative pressure conveying and pumping of liquids to ensure effective and safe transportation of materials.

7. The batching system for powders and liquids includes various batching methods such as "incremental method", "reduction method", and "volumetric method" to ensure accurate proportioning and mixing.

Language

Language

Current Location :

Current Location :